Cabletest for USB 2.0 / 3.0 Typ C and HDMI cable

Cable testing is known to be expensive and cumbersome in cable manufacturing. Sometimes hundreds of thousands of dollars are invested in highly qualified personnel and expensive equipment to ensure that every cable goes through the inspection, sometimes even a restructuring of the production processes takes place. With these concerns, the ACTv2 was introduced as an instrument that combats these obstacles through expensive and difficult to implement cable testing mechanisms. With the Advanced Cable Tester v2 you will find out why cable tests are a cost-effective and advantageous addition to your manufacturing processes:

Affordable tool against expensive equipment and trained personnel

The recognized higher costs for cable testing are an enormous implementation threshold for cable manufacturers. Testing cables in the market is not cheap, as it can potentially cost hundreds of thousands of dollars to implement and run. For those who want to get certifications, such as USB-IF certification, testing can easily take up to a month and often requires exclusive, expensive equipment. The Advanced Cable Tester v2 does not provide conformity certifications, but it does provide the necessary first line of defense ratings for such standards.

Companies often find the testing of individual cables too expensive. It is not always economically justified to perform tests on all cables, especially for those that do mass developments. During the development of the ACTv2, these concerns were identified in cooperation with

the largest manufacturers and the aim was to reduce these costs to just a few cents per test with a design focused on production. With the Advanced Cable Tester v2, this is a small investment compared to the costly consequences that can arise if suitable lengths are not used for quality control.

Our lightning-fast tests are also cost-effective for cable manufacturers. The Advanced Cable Tester v2 carries out every test in just a few seconds. Ideal for production environments where testers can quickly and efficiently perform individual tests on thousands of cables to optimize output. With our easy-to-understand reports and simple confirmation / error confirmation LED screen, testers can easily check the safety and quality of each cable during manufacture at multiple levels. This reduces the effort if several qualified employees are used for quality control.

Versatility in the workplace

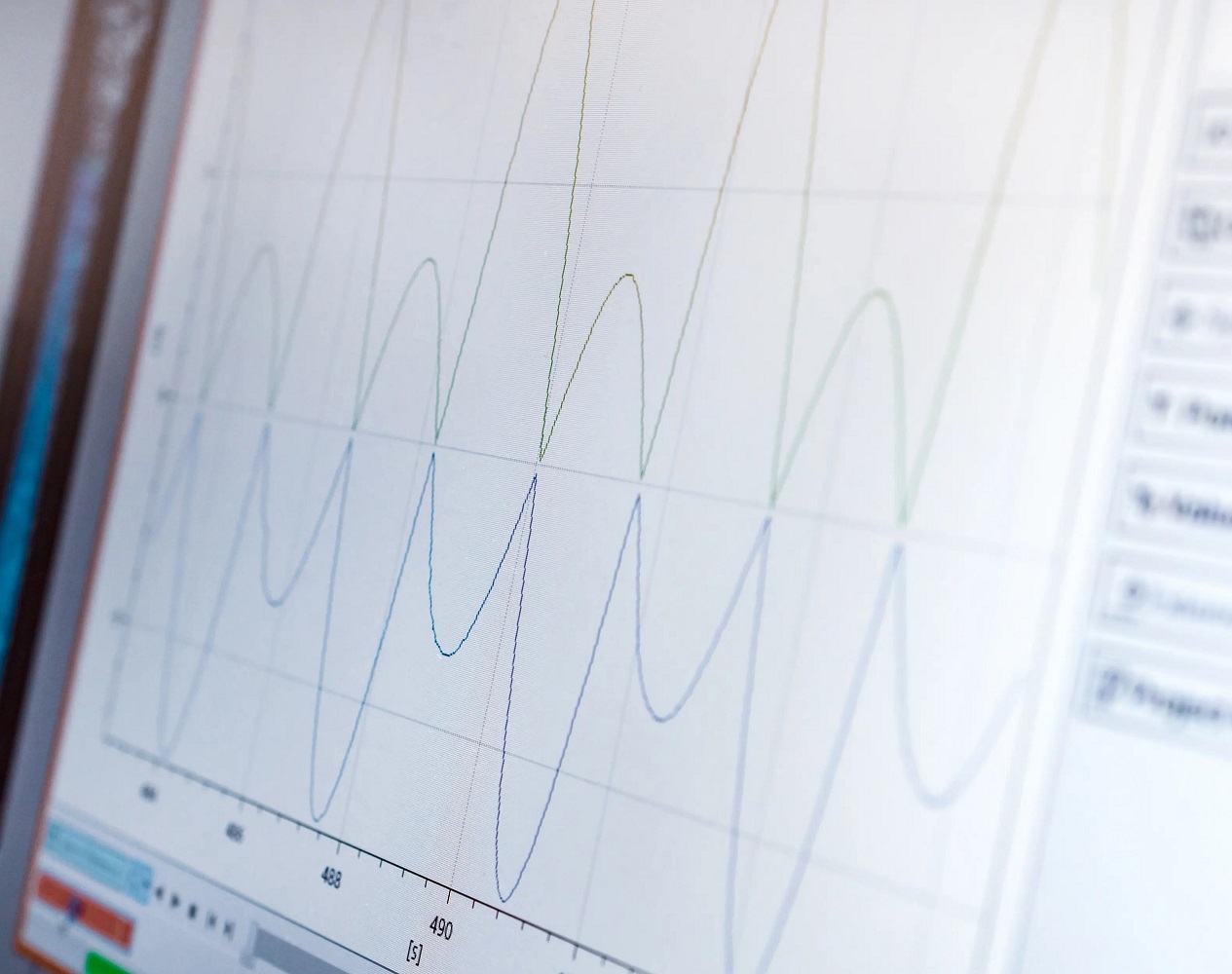

The Advanced Cable Tester v2 offers several different tests that usually require different tools. Our cable tester checks the continuity of the contacts, the IR drop / DCR, the e-marker check and the signal integrity of the cables in a single, compact device. Oscilloscopes that display and analyze waveforms of electronic signals alone can cost up to $ 100,000. Our cable tester has a similar signal integrity test that provides data and the output of signals of different speeds with a coupling eye diagram of up to 12.8 Gbit / s. This gives manufacturers a much easier and cheaper way to check the quality of a cable.

One of the key updates for our next-generation cable tester is extensive support for a wider range of cable types, including USB (Type C, Standard A, Standard B, Micro B), Apple Lightning MFi, and video (HDMI, DisplayPort). Now, even more cable manufacturers can do our extensive testing to ensure that each cable is standard and runs safely. Likewise, manufacturers who manufacture multiple types of cables only need a single solution to cover the entire cable production. Manufacturers can even create their own cable profiles within their Advanced Cable Tester v2 user interface to adapt pass / fail standards. For cables with proprietary or user-defined cables, the Advanced Cable Tester v2 can be adapted to customer-specific connection modules.

The Advanced Cable Tester v2 is also flexible and can be implemented in different environments, be it in laboratories for statistical process control, in production lines for individual quality control or in independent test laboratory settings. Use the Ethernet connectivity and headless mode options to configure remote tests. With the Advanced Cable Tester v2-API, users can easily configure existing test setups and thus enable integration between systems. The implementation of a cable test system in current production structures is no longer costly and time-consuming.

The Advanced Cable Tester v2 is an inexpensive tool for quality control of cables during the manufacturing process.

Catch mistakes before it's too late

Failure to do such extensive testing can have ramifications that can significantly outweigh the initial cost of prevention. The consideration of quality control methods in every phase of the manufacturing process is important - and this goes beyond the validation of the design in the production line. Even in tests and certifications by third parties, it was known that bad cables leave the factory and end up in the hands of consumers. For example, obtaining USB-IF certification or HDMI cable certification is primarily intended to detect design flaws, but manufacturers may be able to overlook manufacturing flaws that are often inevitable.

Detecting errors in continuity, IR drop / DCR, e-marker validation, and signal integrity during the manufacturing process is critical. A single incident can cause the cable to work unexpectedly. Developing cables that go through our rigorous testing can result in fewer product returns, fewer support requests, and minimized product recalls. This leads to higher profit margins and higher customer satisfaction, which contribute to a good reputation and a good brand of the company.

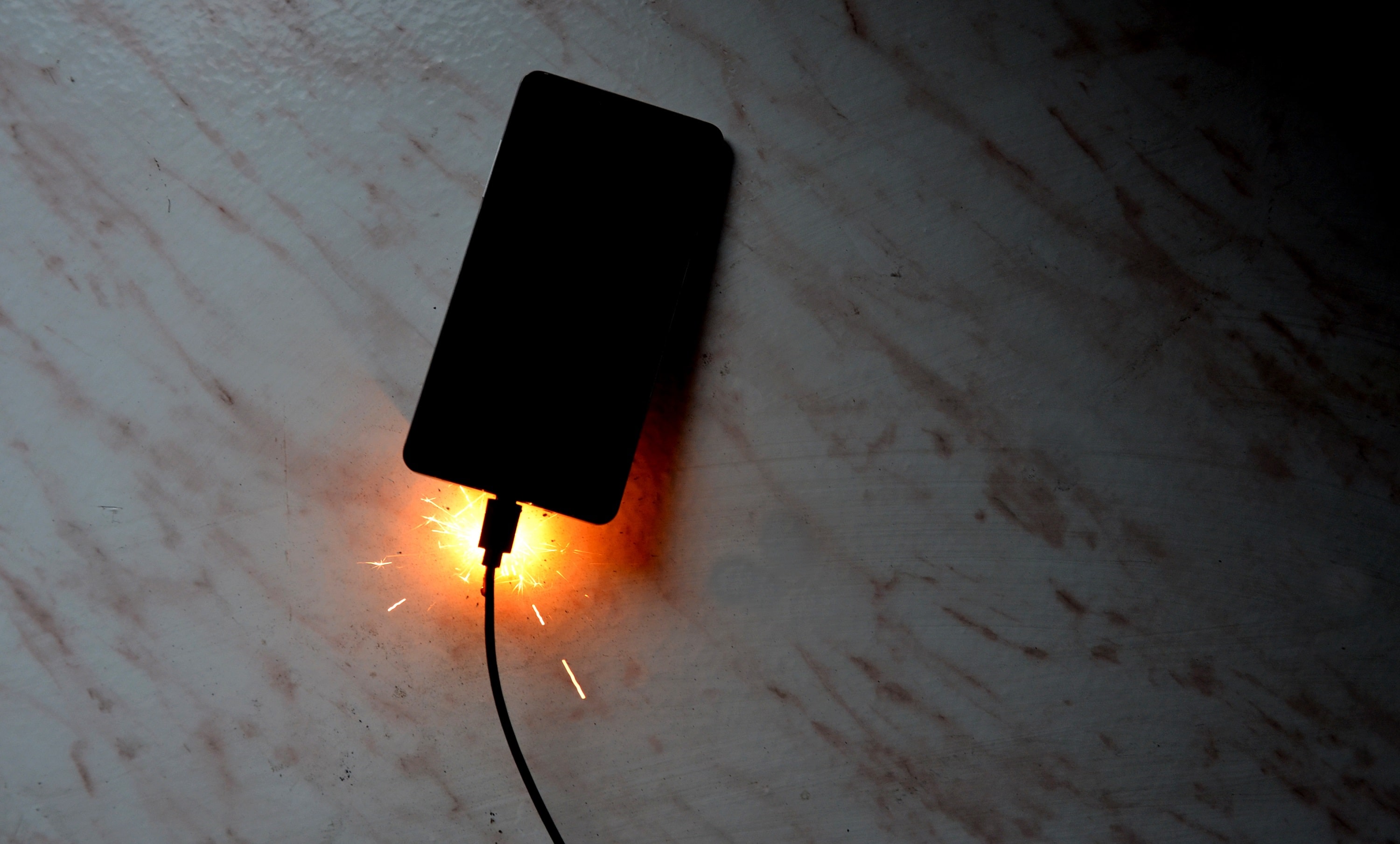

For a quick overview, we look at the dangers associated with devices that catch fire, irreparable damage to devices, and potential lawsuits, expensive recalls, reputational damage, and brand damage. These ramifications can have direct and indirect monetary implications, leading to enormous financial losses that may never be restored. These consequences and risks can be avoided by thorough cable testing in production.

The Advanced Cable Tester v2 removes the expensive, excessive equipment used to test cables and replaces it with a compact, robust design that is flexible in the workplace and allows the manufacturer to adapt to the environment in which it is installed The test can be integrated in the laboratory or in the production line. Investing this tool in manufacturing processes is a cost-effective solution that can save companies from the high cost of using alternative solutions or unexpected consequences.