Description

The Plug & Play CL2000 CAN logger records CAN bus data on an 8 GB SD card and time-stamps it with a real-time clock.

In addition, the CL2000 can act as a CAN bus interface for real-time USB streaming.

The CAN logger is ideal for fleet management (trucks, buses, harvesters, cars, ...), field testing of prototypes, diagnostics or reverse engineering.

Features

- RTC TIMESTAMP

Date and time stamp of your data - important for post-analysis (incl. battery backup) - PLUG & PLAY

Configure in 2 minutes. Power supply via CAN connection. Automatically recognise bit rate - FREE SOFTWARE

Configure your CL1000, stream data and convert log files - COMPACT

Fits in the palm of your hand (6.6 x 4.3 x 2.4 cm) and weighs <50 g - LIVE TRANSMISSION

Easily stream raw and DBC decoded CAN data into SavvyCAN - OWN

Log CAN data for months on an 8-32 GB SD card - no PC required - LOW COST

The value/cost of the CL1000 is very high

Compact CAN logger with SD

With the CL2000 you can log raw CAN data on an 8-32 GB SD card

- 100% stand-alone, no PC required:

- Timestamp data via real-time clock (battery backup)

- Power supply via CAN connection (<1W power consumption)

- Automatically recognise bit rate - no configuration required

- Log raw CAN data in simple CSV format

- Extract data easily from the SD card via USB

- Configure the device via a simple CONFIG.INI file

- Silent mode, filters, transmit lists, cyclical logging

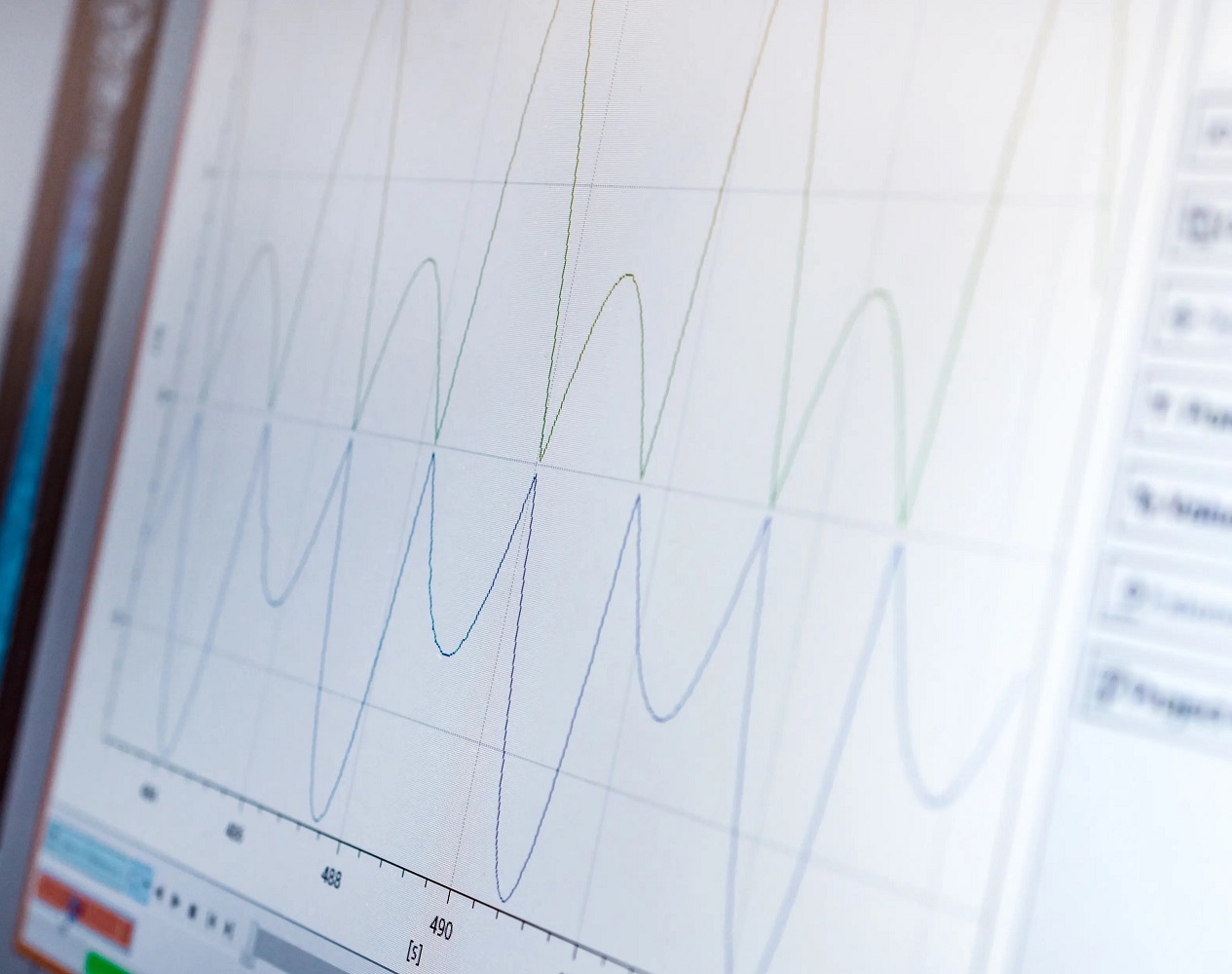

CAN streaming in SavvyCAN

The CL1000 can stream raw CAN data to your PC via USB for real-time analysis:

- Stream raw CAN data in flexible views (filters, traces, ...)

- Send CAN frames with real-time control to your CAN bus

- Display a human-readable form via DBC files (incl. J1939)

- Create real-time diagrams of decoded signals such as speed, rpm, etc.

- Highlight bit/byte changes per CAN ID via the "sniffer view"

- Quickly record "hypothesis signals" for reverse engineering

- Load CLX000 log files for post-processing analysis

Convert log files and decode DBC

The CL1000 also has software tools for converting and decoding log files

- Convert log files to Vector ASC or PEAK TRC

- Decode log files with DBC support in SavvyCAN

- Export the output as CSV for e.g. Excel pivots

Anwendungsbereiche

In some scenarios, you need to record compliance or insurance-related data, e.g. emissions (e.g. NOx, CO, HC, PM, etc.). You may be legally required to log this data from your fleet - even if you don't intend to actively use it. In such a setup, the CL1000 is a simple, cost-effective solution: with an 8-32 GB SD card and cyclic logging, you can log all the CAN, OBD2, FMS or J1939 data you need - and collect it on a case-by-case basis.

If you are not the vehicle manufacturer, you may need to reverse engineer certain proprietary CAN data. Maybe you want to hack your car - or maybe you need to add custom functions in a J1939 test setup. Through data logging, real-time streaming and analysis, it is possible to identify which CAN IDs relate to which parameters - and how the data can be offset/scaled. You can stream data via SavvyCAN or Wireshark, both 100% free and open source.

The CL1000 offers OEM teams a simple tool for collecting vehicle data. The CL1000 is particularly suitable for the late development phase. Here, its compact standalone functionality means it can be added to large fleets of prototype vehicles for long-term logging. After a few weeks or months, the data can be collected and analysed for optimisation and diagnosis.

A non-standalone solution is simply not feasible. However, with the CL2000 you can log data from one or more vehicles or machines for months at a low cost. With cyclic logging, the most recent data is prioritised when there is no more space available. Once the rare behaviour is observed, you have all the data you need to troubleshoot.

F.A.Q.

The CANedge1 is the 2nd generation of the CL2000. Although it does not support real-time streaming via USB, it is designed to be a superior CAN bus data logger. Below we list some of the most important changes in CANedge1.

In general, we recommend CANedge1 for medium and large logging applications - if in doubt, please contact us .

Mechanical

- Extractable SD: The SD can be extracted to transfer data at 80 MB/s (compared to 0.5 MB/s for the CLX000 via USB).

- Industrial SD card: The CANedge uses an industrial SD card, which improves performance and lifetime

- Channels: 2xCAN channels, which enables parallel logging of 2 CAN buses

- Aluminium housing: The new housing is significantly more robust and yet extremely compact

- Power output: supply external modules with power via the 2nd port, e.g. with a DB9-DB9/USB adapter

Protocol files and software/API

- MDF4 protocol files: Popular binary MDF4 format - enables high performance and fast processing

- Configuration: Open source configuration editor can be used online or offline via your browser

- JSON schema: Configuration files are based on the standardised JSON schema concept, which is supported by many open source tools

- asammdf GUI : Enables user-friendly editing of MDF4 log files, DBC conversion (incl. OBD2/J1939), graphical representations and more

- Python API : Easily process your data at scale and automate the creation of e.g. reports/databases/dashboards

- Converter : Open source C++ converters enable drag & drop/CLI conversion of MDF4 files to e.g. *.csv, *.asc, *.trc

Data acquisition

- Lossless: The CANedge can log extreme bus loads without message loss (the CLX000 is limited to ~1000 frames/sec.)

- Extended configuration: Extended filters and transmission lists (e.g. up to 128 filters compared to 8 for the CLX000)

- Precision: 20 times higher RTC resolution (50 microseconds) - with extended WLAN RTC synchronisation

- Boot time: Much faster boot time compared to the CLX000 (~1 sec. vs. ~10 sec.)

- CAN FD: The CANedge supports CAN FD (Flexible Data Rate) and is therefore future-proof

- LIN bus: Supports LIN bus data logging (slave mode)

The CLX000 series can log data from any high-speed CAN bus application (ISO 11898-2). In practice, this includes raw data from almost all vehicles (cars, trucks, tractors, forklifts, buses, motorbikes, ...) - as well as various production machines, EV batteries and more. Most aeroplanes and boats also use the CAN bus. In terms of protocols, this includes J1939, CANopen, NMEA, FMS, OBD2 and more.

For the specific case of OBD2, the CLX000 can send up to 20 customised CAN messages periodically, which means it can be used as an OBD2 data logger. Note, however, that you need to check whether your car uses CAN as the basis for OBD2 communication (this is the case for all US cars manufactured after 2008, for example). Also note that all cars differ in the number of OBD2 parameters supported - and of course the CLX000 can only record the supported data.

The CLX000 series can be supplied with power via the CAN bus. This means that you simply connect the device via the DB9 connector to supply it with power. In cars, you normally need a DB9-OBD2 adapter, while for trucks, for example, you can use a DB9-J1939 adapter.

Once the connection is established, the CLX000 starts recording data - and due to its extremely low power consumption, you can simply leave it in the vehicle. In most vehicles, the CLX000 switches off when the vehicle is switched off. If this is not the case, the power consumption of the logger itself is still not a problem in terms of battery consumption. However, if you request OBD2 data in this scenario, for example, the request may activate the vehicle's control units. In this case, you should avoid leaving the CLX000 switched on in an unused car for more than a few days.

Note that the CLX000 can also be powered via USB when it switches to "mass storage device mode" - so you can configure the logger on your PC without a separate power source.

The 8GB SD card offers an enormous capacity for the CL2000 CAN bus data logger. Whilst memory usage varies depending on the application, 8GB is sufficient for continuously logged data over many weeks. As most vehicles do not drive continuously, this typically equates to months of data.

If you need to log data over a very long period of time, you can either upgrade to a 32 GB SD card or pre-log your data at a lower frequency (e.g. only log every 10th or 100th message). Finally, you can add filtering to limit your logging to specific CAN IDs or J1939 PGNs. Please refer to the product manual for more details.

The CL2000 CAN bus analyser has a real-time clock with battery backup. This means that your CAN bus data is 'time stamped' - i.e. each CAN frame logged on the vehicle network is time stamped so that you can link the observed CAN data patterns to real-time events.

This is critical in applications where you are comparing your CAN bus data with physical events (e.g. weather conditions, time of day, physical interaction with the vehicle, etc.). Also, once you are logging data over several days, it can be difficult to keep track of your data if you have not recorded the date and time. In practice, we therefore always recommend using a CL2000/CANedge CAN logger if you primarily want to record vehicle/machine data and not stream it in real time.

Technical Data

| Model specification |  CL2000 |

|---|---|

| Functionality | Data logger and real-time CAN interface |

| LEDs | Logger status via three externally visible LEDs |

| Firmware | Supports free firmware updates to add functions |

| Software | Free executable files for conversion to ASC/TRC [Windows/Linux] Free open source software SavvyCAN for streaming/analysing CAN data + DBC decoding [Windows/Linux] The .INI config/.TXT log files can also be easily opened in text editors or scripts [Windows/Linux] |

| Safety and security | CE, FCC, IC and RoHS certified |

| Standard | Compatible with the physical layer standard ISO 11898-2 |

| Identifier | Complies with CAN specifications 2.0A (11-bit ID) and 2.0B (29-bit ID) |

| Bit rate | Bit rates up to 1 Mbit/s (manually configured or automatically recognised) |

| Automatic bit rate detection | Yes |

| Protocol support | Protocol-independent (i.e. can log CAN, J1939, CANopen, OBD2, etc.) |

| Filter | Advanced message filtering on four configurable channels |

| Silent mode | Yes (has no influence on CAN bus transmission) |

| Fail-safes | The device does not terminate the CAN bus internally |

| SD card | Exchangeable 8 GB SD card (optional 32 GB) |

| Real-time clock | Yes (CAN messages are provided with a time stamp with a resolution of 1 ms) |

| Control signal | Logging status (enabled/disabled) can be changed at runtime using a CAN bus control message |

| Heartbeat signal | Supports the heartbeat signal for regular display of the logger status |

| Cyclic logging | Supports cyclic logging mode (oldest log file is deleted when the file system is full) |

| Downsampling | CAN ID-specific message downsampling to reduce the frequency of logged messages |

| Transmit | transmit up to 20 individual CAN bus messages (e.g. for OBD2). Full real-time transmission control via USB |

| File system | Standard FAT file system |

| Frames/second | The CL2000 can log/stream approx. 800-1000 frames/sec. without loss. Information on higher bus loads can be found in the CANedge |

| Power supply via CAN connection | Power can be supplied via the DB9 CAN connection (log/stream) or via USB (data extraction). |

| via CAN connection (DB9) | Power supply via the CAN bus (+7.0 V to +32 V DC) |

| Protection | Reverse polarity protection on the CAN bus supply Protection against transient voltage pulses on the CAN bus supply |

| Power supply via USB | Power supply via USB (+5.0 V DC) for data extraction/configuration |

| Power consumption | The power consumption of the logger is approx. 1 W |

| Housing | Robust, small housing |

| Dimensions | 66.7 x 42.7 x 23.5 mm (L x W x H) |

| Weight | 45 grams |

| Connector | Standard D-Sub-9 connector (DB9) (OBD2, J1939, "general" adapter optional) |

| USB PORT | Standard mini-USB port (B) for extracting data and data Streaming (cable not included in the scope of delivery) |

| Operating temperature | Operating temperature: -20 °C to +65 °C |

| Real-time clock | Built-in real-time clock with calendar and battery backup |

| IP rating | IP rating 40 |

| Model comparison |  CL1000 |  CL2000 |  CANedge1 |  CANedge2 |  CANedge3 |

|---|---|---|---|---|---|

| Number of CAN channels | 1 | 1 | 2 | 2 | 2 |

| Number of Lin channels | - | - | 2 | 2 | 2 |

| CAN FD | - | - | Yes | Yes | Yes |

| RTC timestamp | - | Yes (1ms) | Yes (0.05 ms) | Yes (0.05 ms) | Yes (0.05 ms) |

| Frames per second | ~800-1000 | ~800-1000 | 3000+ | 3000+ | 3000+ |

| Logging to SD card | Yes | Yes | Yes | Yes | Yes |

| Industrial and extractable SD | - | - | Yes | Yes | Yes |

| Log file format | .txt | .txt | MDF4 (.MF4) | MDF4 (.MF4) | MDF4 (.MF4) |

| Cyclical logging | Yes | Yes | Yes | Yes | Yes |

| Silent mode | Yes | Yes | Yes | Yes | Yes |

| Automatic bit rate detection | Yes | Yes | Yes | Yes | Yes |

| Filter and prescaling | Basic | Basic | Advanced | Advanced | Advanced |

| Transmit lists | Basic | Basic | Advanced | Advanced | Advanced |

| Control signal (trigger) | Basic | Basic | Extended | Advanced | Advanced |

| Data compression and encryption | - | - | Yes | Yes | Yes |

| Logging of CAN/LIN error frames | - | - | Yes | Yes | Yes |

| USB streaming to PC | Yes | Yes | - | - | - |

| GNSS/IMU support | - | - | Optional | Optional | Yes |

| Secure WLAN/LTE data transmission | - | - | - | W-lan | 3G/4G LTE |

| Over-the-air configuration/firmware | - | - | - | Yes | Yes |

| Configuration editor | Yes | Yes | Yes | Yes | Yes |

| Support for DBC conversion | Yes | Yes | Yes | Yes | Yes |

| Convert data to e.g. ASC, TRC | Yes | Yes | Yes | Yes | Yes |

| Graphical plot support | - | - | Yes | Yes | Yes |

| Data processing API | - | - | Yes | Yes | Yes |

| Dashboard integration | - | - | Yes | Yes | Yes |

| Telematics cockpit | - | - | - | Yes | Yes |

| L x W x H (mm) | 67 x 43 x 24 mm | 67 x 43 x 24 mm | 75 x 47 x 20 mm | 75 x 47 x 20 mm | 75 x 47 x 20 mm |

| Weight (g) | 50 | 50 | 100 | 100 | 100 |

.jpg)

.jpg)

.jpg)

.jpg)